All the world’s talking about Digital Twin – but let’s think a little further ahead than that. Digital Twin is just the first step, not the end destination. Mesh Twin Learning is the next phase – so let’s explore that and provide a number of key benefits that MTL is ready to provide!

The State of Manufacturing

Industry 4.0 and smart factories are gaining momentum. According to research Deloitte conducted together with MAPI, 86% of manufacturers believe smart factory initiatives will be the main driver of competitiveness in the industry. Smart factory initiatives are already taking 30% of global factory budgets and, moreover, 58% of respondents expect an increase in their smart factory budget in 2020.

All of these are good reasons why the smart factory is getting such interest in the manufacturing industry. Of course – it’s also providing significant benefits. Early adopters of smart factory initiatives report double digit growth in KPI between 2015 and 2018. On average, they reported a 10% increase in production outputs, 11% in factory capacity utilisation and a 12% increase in labour productivity.

According to KPMG and a survey regarding the UK automative industry, the many benefits of digitalisation initiatives include:

- A 20-35% reduction of machine downtime

- A 15-25% reduction in plant maintenance costs

- A 12-20% reduction in inventory

- Up to 80% improvement in forecasts accuracy

- A 30 – 50% increase in productivity

Digital Testing & Real Benefits

The Smart factory promises a lot. Higher productivity, quality improvements and reduced costs, to name just a few examples. All of this can be achieved by creating the digital copy of a factory and, eventually, the entire factory network.

The direct experience of early adopters proves that digitalisation is the way to go for manufacturing companies, but those who follow this path will encounter many challenges. Mesh Twin Learning is the solution that makes the journey easier – so let’s get into the important details!

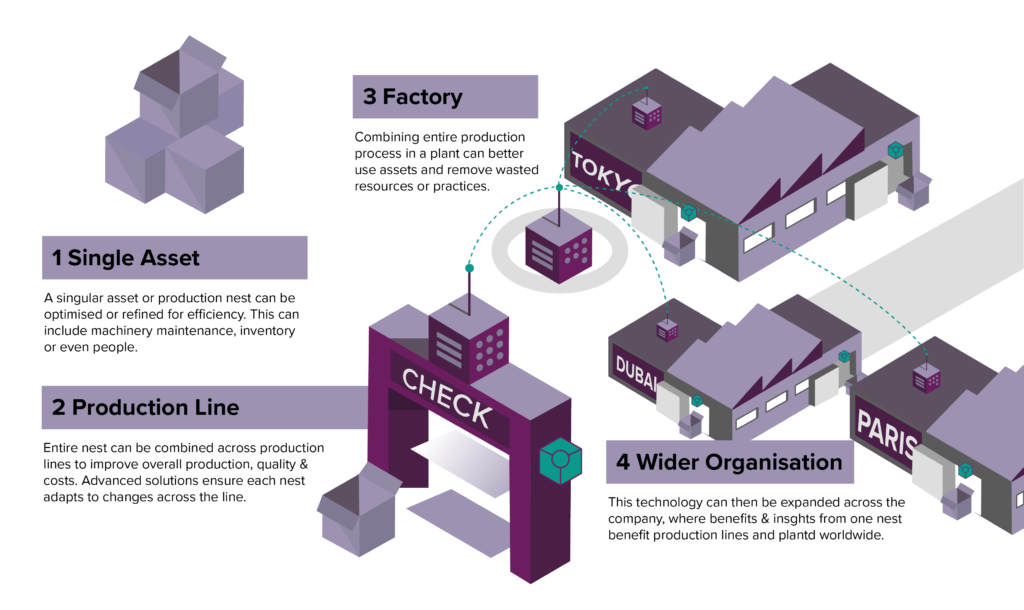

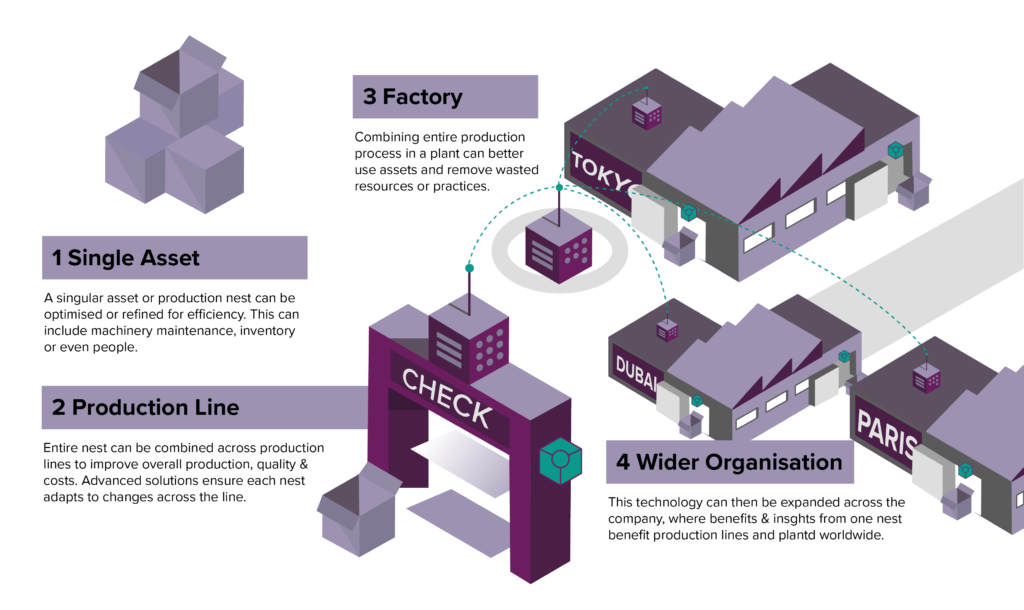

From Digital Twins of Single Asset to the Factory Network

One of the most vital Industry 4.0 cornerstones is the Digital Twin; the virtual copy of a physical asset. Digital twins store various types of data about the respective physical assets, from CAD designs and optimal performance parameters to maintenance reports and real-time data collected by IIoT sensors.

Even the Digital Twin of a single asset and simple real-time data visualisation is the solution that generates lots of business value. This includes Improved visibility results in more informed decisions, improved performance and better issues detection. We’ve previously spoken about the Digital Twin technology in broader context here (and here), so let’s focus on taking it to the next level.

The value digitalisation initiatives provide is a benefit that grows exponentially with the scale of the solution, from a single asset to a network of factories. Connecting the digital twins of factories and supply chains opens a whole new world of innovation and optimisation possibilities.

Like most of the game changing concepts, Industry 4.0 and its digital factories come with a unique set of hurdles. There are various business challenges, namely defining digitalisation strategy, selecting initiatives of the highest value, deciding where to start and even convincing employees to break the status quo and embrace the change.

There are also technical challenges, too, such as what technologies to use, what architectures to choose, how to ensure data storage capabilities and even the high computational power required by Big Data and Machine Learning technologies.

In fact, implementing digital factory would be a challenge even in a greenfield project scenario – I by no means want to give you the impression that it’s a one-click deployment. The truth is that most smart factory projects are targeted at existing facilities, rather than during the planning and construction of completely new factories. After all, companies want to get as much as they can from the facilities and inventory they already have.

Existing production facilities often consist of a mix of assets, from old yet fully functional machines that require retrofitting to modern devices that are already equipped with IIoT sensors. This results in various communication standards, data formats and more. On top of that, high-performance internet connections are required to exchange vast amount of data, which is rarely seen at most existing production facilities.

Mesh Twin Learning

Mesh Twin Learning (MTL) is a solution that combines various modern technologies to solve many of the technological challenges related to the digital factory, particularly with digital factory networks.

Figure 1. MTL: high-level architecture

As an overview, MTL mixes modern technologies and disciples, which are:

- Industrial Internet of Things (IIoT) – sensors and other devices networked together with industrial software. This connectivity allows for data collection, exchange and analysis.

- Edge Computing – A type of system architecture, wherein data storage and computing capabilities are moved to edge locations. This is supported by specialised devices connected to the global network, allowing for distributed computing with immediate access to results and seamless communication with Cloud resources. You can learn more about Edge Computing here

- Cloud – A large network of interconnected data centres, which operate as a single ecosystem, providing the necessary resources, computing power and services to run applications or deliver the content to end-users.

- Digital Twins – A virtualised copy of a physical device, component or living entity, which represents its state as series of parameters constantly monitored and updated in time. This enables the digitisation of everything from processes, systems and places – even up to people themselves. Digital Twins enable advanced simulations, better monitoring and more effective decision making over a distributed system’s state.

- Machine Learning – A concept that builds capability to automatically learn and improve from experiences. It uses available data, without being explicitly implemented as set of static behaviours.

- Data Science – A set of scientific methods and techniques, aiming to extract knowledge from various surroundings, as well as use structured and unstructured data from all available sources, to support all processes focused on decisions, predictions or business management.

- Mesh – An approach to building, scaling and operating distributed ecosystems. The main focus is put on security, connectivity and the reliability of the designed architecture. This is implemented to limit the need for full assets sharing, instead introducing cross-functional capabilities of various parts of the system.

How companies can benefit from Mesh Twin Learning

Mesh Twin Learning addresses common technical challenges related to digital transformation. By doing so it provides business benefits:

1. Interoperability

Greenfield projects are rare in the field of digital transformation and especially so in manufacturing. Most projects are attempting to digitalise already existing processes and physical devices. Older machines often do not have IIoT sensors and require retrofitting, while newer machines already feature IIoT sensors.

The problem is that these sensors use different communication standards, send data in different structure and are configured in different ways. This becomes an even larger issue when we deal with digitalisation of many factories. MTL features dedicated edge devices as connectors between specific machines and common data, with a Machine Learning repository in the cloud. Each edge device collects data from the machine, including its sensors, and sends instructions prepared for the machine.

Data collected by these edge devices is then sent to the central data repository in the Cloud, where it can be transformed to the common standard before being analysed, visualised and fed to machine learning models.

2. Better Performance Monitoring, Faster Decisions

A central repository, fed with data from edge devices, enables the creation of dashboards that can provide company-wide, near real-time view on assets and processes. With such a central command point, executives and managers can rely less on their experience and intuition – instead, they will have data they need to make decision exactly when they need it.

A central dashboard not only supports decision making, but also facilitates performance monitoring on a company scale. Dashboards present process KPIs and machine performance, which help discover bottlenecks and track potential issues before they become serious malfunctions and cause downtimes and subsequent loss of revenue. After all, a factory that isn’t producing, isn’t profiting.

3. Self-optimising factories

One of main elements of Mesh Twin Learning is Machine Learning – more specifically, the competition between Machine Learning models. The Cloud component of MTL includes a Machine Learning engine, with multiple models fed with data from the edge devices.

This Engine constantly tries to optimise models to enable the best possible performance for each process or machine they are responsible for. Models that have the same task, for instance improving quality of the phosphors in a LED lights manufacturing factory, are fed with data from different physical devices, such as different production lines. This means each model adapts to different changes in the process.

Once models are trained in the real world and subsequently tested in a digital replica. Models are applied to processes executed in the virtual, simulation engine and their results are compared. Those which provide the best results can be automatically distributed to edge devices, where they are then applied to real processes.

4. Maximising Performance for Faster Innovation

With access to company-wide data, employees have the opportunity to discover new patterns, notice dependencies between processes and derive insights to enable further improves to process performance, reduce stocks and so on. With a factory network enabled by MTL technology, businesses can see the capacity utilisation of all factories and jointly plan processes across the network, using real-time production and inventory data to minimise waste and cycle time.

Furthermore, Machine Learning models that are already deployed to the central Machine Learning engine are constantly testing new process variable settings to improve performance. They are doing this 24/7 and at a pace much higher than any people could achieve.

Likewise, MTL provides the capability to test models via the simulation engine before applying them to the physical process. This way, results are provided much faster, as the only limitation is computing power, which is almost limitless in the Cloud. This simulation engine is also the place where the Data Science team can test new concepts in no time at all – with no consequences to the real-world process.

5. Easier change management

Implementing changes take time. In the context of digital factories, there are various types of changes MTL helps with, including edge device configurations and changes to settings related to the business processes, such as business rules and alerts thresholds.

There are also changes to Machine Learning models deployed to machines. Managing such a complex environment manually would be very time consuming and error prone.

MTL, however, provides a central repository of edge device configurations, business rule engine configuration and Machine Learning models. Such a central repository includes a registry of physical assets and knows exactly what changes should be deployed – and where. This means new versions of the Machine Learning model or edge device configuration can be deployed to all devices in several minutes, instead of days.

Summary

If one digital twin is great, and two is better, than an entire mesh of networked Digital Twins is absolutely full of value. Hopefully, as I’ve shown, properly networked Machine Learning models can implement network-wide benefits faster than any other means, leading to bigger advantages, delivered on a wider scale and at previously unthought of speeds. It’s not overnight success, but the long-term results are certainly worth it.

Sources

- The Smart Factory: Responsive, Adapative, Connected Manufacturing [Deloitte]

- 2019 Deloitte and MAPI Smart Factory Study

- The Digitalisation Of The UK Automotive Industry